- Dongying Mingde Petroleum Technology Co., Ltd

-

Qingdao, Shandong, China

- Main products: Slotted Liner , Wire Wrapped Screen, Premium Mesh Screen, Drilling Fluid Chemicals, Plasma slotted liner , Tubing Pup Joint, Laser Slotted Liner, Pup Joint and Crossover, Tubing and Casing Coupling, Liner Hanger, Float Collar and Float Shoe, Foaming Agent for Drilling Fluids

Home > Blog > Why Your Well is Producing Sand (And What to Do About It): A Guide for Oil & Gas Operators

-

Qinghua Lv

Hi there! Welcome to my shop. Let me know if you have any questions.

Qinghua Lv

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Why Your Well is Producing Sand (And What to Do About It): A Guide for Oil & Gas Operators

2025-07-17 17:37:32

Sand production is one of the most persistent and costly challenges in oil and gas production. It damages equipment, restricts flow, increases downtime, and poses significant safety risks. Understanding why sand enters your wellstream is the critical first step towards implementing effective solutions and protecting your assets.

At Dongying Mingde Petroleum Technology Co., Ltd., we specialize in diagnosing and solving sand control problems. Let's delve into the primary reasons your well might be producing sand:

1. Weak or Poorly Consolidated Formations:

The Cause: This is the most fundamental reason. Some reservoirs, especially younger geological formations (like many unconsolidated sandstones or shallow heavy oil deposits), simply lack the natural cementation (clays, carbonates) to hold sand grains together effectively. The formation rock strength is inherently low.

The Effect: Even moderate fluid drag forces during production can dislodge sand particles.

Mitigation: This scenario almost always requires proactive sand control measures like screens, gravel packs, or chemical consolidation before significant production begins.

2. Reservoir Pressure Depletion:

The Cause: As reservoir pressure declines over the life of the field, the effective stress on the formation rock increases. Think of it like removing support – the weight of the overburden rock presses down harder on the reservoir rock.

The Effect: This increased stress can crush weak rock grains or overcome the natural bonding forces, leading to failure and sand production, even in formations that were initially stable.

Mitigation: Careful reservoir management, maintaining pressure where possible (e.g., water/gas injection), and implementing robust downhole sand control are crucial.

3. Excessive Production Rates / Drawdown:

The Cause: Pulling too hard on the reservoir. High fluid flow velocities near the wellbore create significant drag forces on sand grains. High drawdown (difference between reservoir pressure and bottom-hole flowing pressure) increases the effective stress locally around the well.

The Effect: These combined forces can overcome the formation's strength, dislodging sand particles and potentially leading to localized failure ("cavitation") or even larger-scale sand influx.

Mitigation: Optimizing production rates to stay below the critical sand-free drawdown limit for your specific well is key. This requires careful monitoring and choke management.

4. Water Breakthrough / Increased Water Cut:

The Cause: Water production significantly impacts sand stability in several ways:

It reduces the relative permeability to oil, often requiring higher drawdown to maintain rates, increasing stress.

Water can dissolve natural cementing materials (like carbonates).

It increases the drag force due to higher fluid density and viscosity compared to oil/gas.

Water can cause clay swelling or fines migration within the pore structure, weakening the matrix.

The Effect: Wells that were previously sand-free often start producing sand soon after water breakthrough. Water is a major destabilizing factor.

Mitigation: While water breakthrough is often inevitable, its impact can be managed through rate control, chemical treatments to inhibit fines/clay issues, and ensuring adequate sand control is in place before water arrives.

5. Inadequate or Failed Completion Design:

The Cause: The initial downhole completion may not have included effective sand control, or the chosen method (e.g., standalone screen type/size, gravel pack design, frac-pack execution) may have been unsuitable for the actual downhole conditions encountered or deteriorated over time due to erosion, corrosion, or plugging.

The Effect: Sand enters the wellbore unimpeded or through damaged control equipment.

Mitigation: Proper initial design based on comprehensive formation analysis and robust installation techniques are vital. Regular well integrity monitoring helps detect failures early.

6. Formation Damage During Drilling/Completion/Workovers:

The Cause: Invasive drilling fluids, incompatible completion fluids, poor cementing jobs, or aggressive stimulation treatments (like acidizing or fracturing near the wellbore) can weaken the formation rock or damage the natural cementation around the well.

The Effect: Creates a zone of weakness near the wellbore, making it more susceptible to sand production even under normal operating conditions.

Mitigation: Employing formation-friendly drilling/completion fluids, optimizing stimulation designs, and ensuring good cement bonding are essential preventative measures.

7. Natural or Induced Fractures & Geomechanical Stresses:

The Cause: Tectonic stresses or induced stresses from production/injection can create or reactivate fractures in the formation. Highly stressed intervals are prone to failure.

The Effect: Sand can enter the wellbore through these fracture networks, sometimes in bursts associated with stress changes.

Mitigation: Understanding the local stress regime and designing completions accordingly is complex but important. Targeted sand control across fractured zones may be needed.

Don't Let Sand Drain Your Profits

Sand production isn't just a nuisance; it erodes chokes, valves, pipelines, and surface facilities, leading to expensive repairs, unscheduled shutdowns, deferred production, and safety hazards. Ignoring it leads to escalating costs and potential well failure.

Partner with Dongying Mingde for Sand Control Solutions

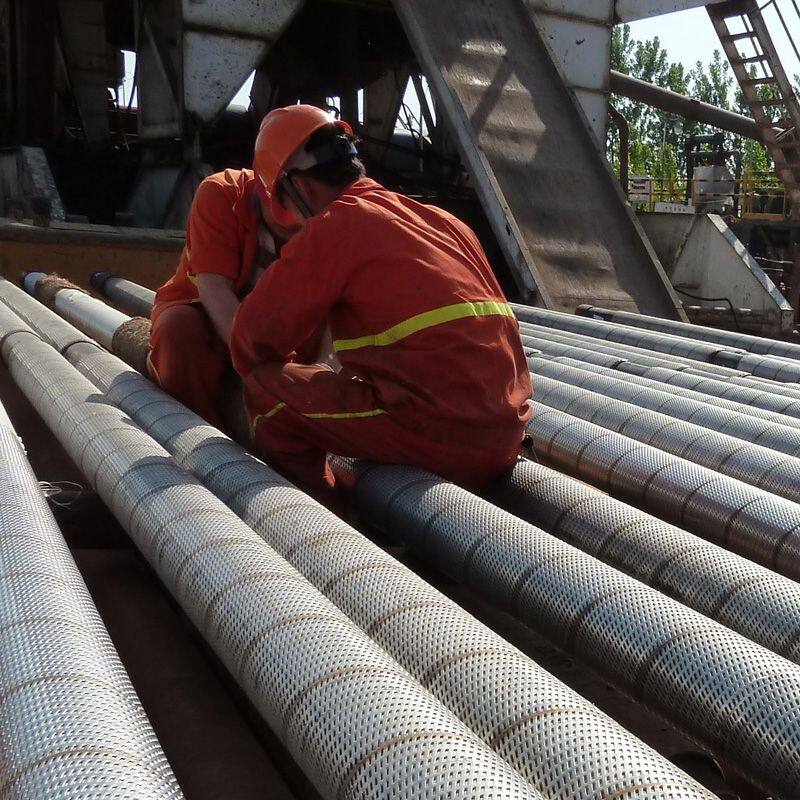

Understanding the root cause of your sand production is paramount to selecting and implementing the right, cost-effective solution. At Dongying Mingde Petroleum Technology Co., Ltd., we offer comprehensive sand management services:

Sand Production Diagnosis & Prediction

Advanced Sand Control Design & Engineering (Screens, Gravel Packs, Frac-Packs, Chemical Consolidation)

Sand Monitoring Equipment & Services

Remedial Sand Control Solutions for existing problem wells

High-Quality, Durable Sand Control Products

Take Control of Your Well's Integrity.

Contact Dongying Mingde Petroleum Technology Co., Ltd. today for a consultation. Let our experts help you diagnose your sand production issues and implement reliable, long-lasting sand control strategies to maximize your well's productivity and lifespan.

Keywords: Sand Production, Sand Control, Downhole Sand, Well Sand Issues, Sand Management, Oilfield Sand Solutions, Sand Prevention, Gravel Pack, Sand Screens, Formation Damage, Reservoir Management, Well Integrity, Completion Design, Erosion, Dongying Mingde, Petroleum Technology, Oil and Gas Production Problems.

Tags: Sand Production Solutions, Reservoir Management, Dongying Mingde Petroleum Technology